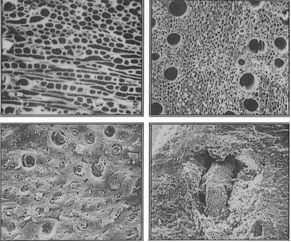

Activated carbon is an amorphous form of graphite with a highly developed internal pore structure that gives the material its’ unique adsorptive properties.

There are a wide variety of activated carbons, each exhibiting their own adsorptive characteristics, dependant upon the raw material used and the process technique adopted. These characteristics determine which applications the activated carbon is most suited to.

PT. Freeman produces activated carbons from coconut shell, utilizing the steam activation technology in rotary kilns. The use of coconut shell facilitates the manufacture of products with very high adsorptive capacities, coupled with a natural hardness that renders the carbon highly resistant to physical breakdown through attrition.